Automotive and metal stamping parts

In vehicle manufacturing, 60% to 70% of metal components are stamped parts. From the exterior of the car body to the tiny conductive terminals inside, stamped parts form the shape, skeleton, and nerves of the car.

The following is a detailed explanation of the specific role and application scenarios of metal stamping parts in the automotive industry:

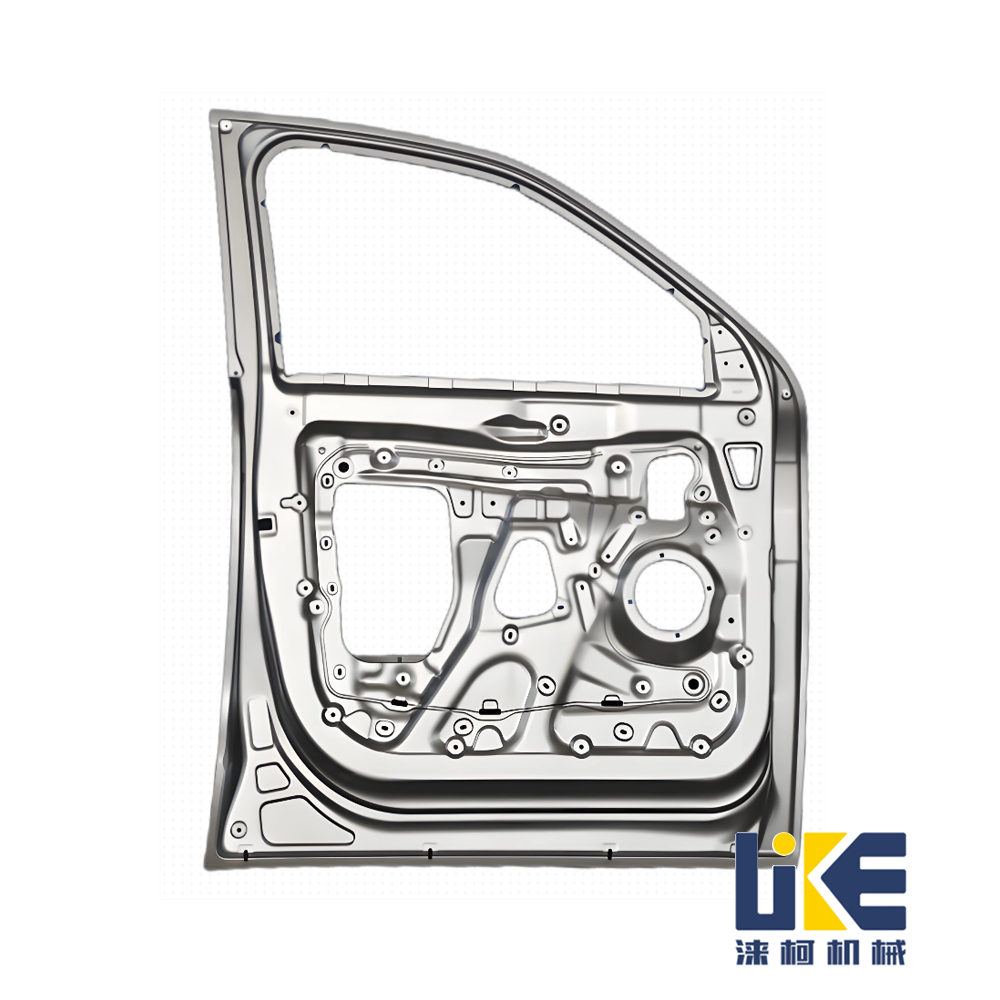

1. Body Panels/Class A Surfaces - The "Skin" of Cars

This is the most intuitive part of automotive stamping, which directly determines the appearance, aerodynamics, and sealing performance of the car. These types of parts are commonly referred to as "A-grade surfaces" and require extremely high surface quality.

Four doors and two covers:

Hood/Bonnet、Trunk Lid、Door Panels、Roof。

Process: Mainly stretching and shaping. The surface must be absolutely smooth, without any waves, pits or scratches, otherwise it will be very noticeable after painting.

Fenders:

The curved plate above the wheel has a complex shape and requires multiple stamping processes to complete.

2. Body Structure/BIW - the "skeleton" of a car

These parts are hidden under the skin, forming the Body in White. They are responsible for bearing loads, absorbing impact energy, and protecting the safety of passengers inside the vehicle.

Pillars & Rails:

A-pillar, B-pillar, C-pillar: These parts are usually stamped with ultra-high strength or hot formed steel.

Function: To prevent the cockpit from deforming and squeezing passengers during rolling or side collisions.

Floor Pan & Chassis Rails:

The huge metal plates and reinforcing beams at the bottom of the car are the foundation of the entire vehicle.

Bumper Beams:

The metal crossbeam inside the front and rear bumpers is usually stamped from cold-rolled high-strength steel and used for hard impact protection.

3. Chassis&Suspension - The 'legs' of a car

Chassis components are usually stamped with thick plates (thickness 2mm-6mm), requiring extremely high strength and fatigue life.

Control Arms:

The components that connect the wheels and the body of the vehicle. Previously, casting was commonly used, but now in order to reduce weight, double-layer steel plate stamping and welding structures are widely used.

Subframe:

The frame supporting the engine and suspension is welded from multiple thick stamped parts.

Brake disc dust cover:

The thin metal plate behind the brake disc prevents mud and sand from entering the brake system.

4. Powertrain - Differences between gasoline and electric vehicles

In this field, the role of stamped parts is undergoing a significant transformation.

ICE:

Oil Pan: A box for storing engine oil at the bottom of the engine, deep drawn stamping parts.

Valve cover: The cover on the top of the engine.

Heat Shields: The corrugated aluminum plate around the exhaust pipe prevents the body from being damaged by high temperatures and is a typical thin plate stamping.

New Energy Electric Vehicles (EVs) - The Fastest Growing Field:

Battery Pack Case: A large battery tray typically assembled from aluminum alloy stamped and extruded parts, requiring extremely high sealing and collision resistance.

Drive motor stator and rotor: made of hundreds of high-speed stamped and stacked silicon steel sheets, directly determining the efficiency of the motor.

Busbars: Copper bars inside battery packs that transmit high currents are stamped and bent components.

5. Interior & Seating

Seat Frames:

The slide rails, backrest adjusters, and base inside the seat are all made of high-strength steel stamped parts. They must hold passengers in the collision without breaking.

Seat belt buckle:

The mechanical structure inside the lock tongue and lock buckle is a precision stamped part that has undergone heat treatment, which is related to life safety.

Instrument panel bracket:

The CCB that supports the screen and instruments inside the center console is welded from pipes and stamped brackets.

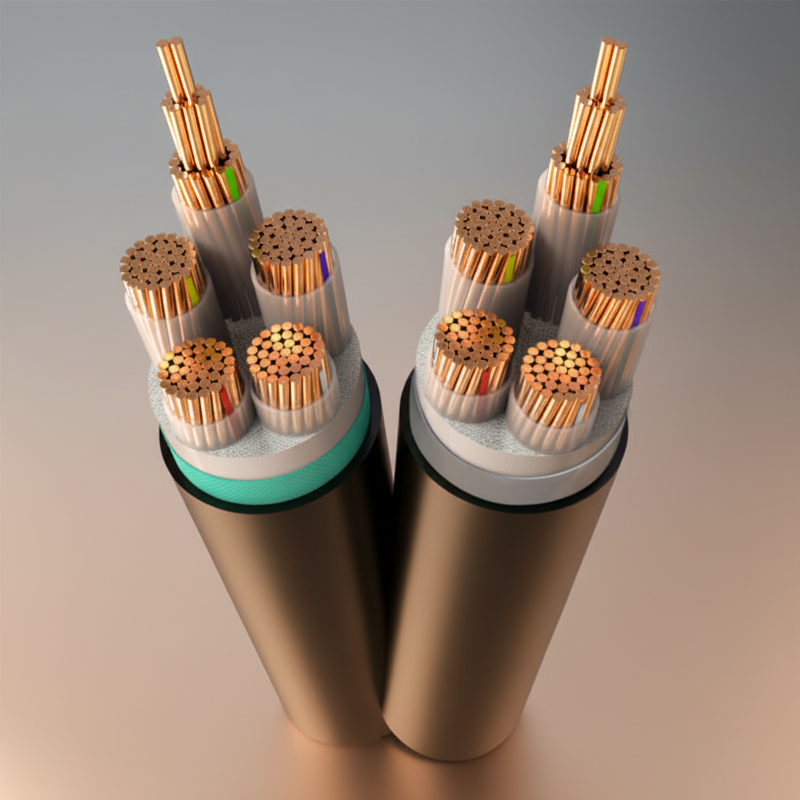

6. Electronics

Modern cars have thousands of connection points.

Terminals: Copper springs in the wiring harness plug.

Lead Frames: The internal support structure for in car chips and sensors.

Why is the automotive industry the culmination of stamping technology?

Efficiency:

The annual production of automobiles can easily reach millions of units. Stamping technology (especially multi station progressive dies and transfer dies) can achieve the production of 10-20 large coverings per minute, or hundreds of small brackets per minute. This is an efficiency that CNC or 3D printing cannot match.

Lightweighting:

In order to save fuel and increase range, cars must be reduced in weight. The stamping process combined with high-strength steel and aluminum alloy can thin the parts while maintaining extremely high strength.

Material utilization rate:

Compared to cutting, stamping can minimize waste and control vehicle costs to the greatest extent possible.

Consistency:

Cars are highly standardized products. The stamping die ensures perfect dimensional accuracy matching between the left and right front doors, ensuring interchangeability of parts.

summary

In the automotive industry, metal stamping parts are the absolute protagonists.

The streamlined body that you can see is stamped out;

The sturdy frame that protects your safety is stamped out;

The iron core of the motor that drives the vehicle is also stamped out.

The level of automobile manufacturing largely depends on the design capability of its stamping molds and the degree of automation of the stamping production line.

Ventilation systems and metal stamping parts

Ventilation systems and metal stamping parts

Automotive and metal stamping parts

Automotive and metal stamping parts

Cables and metal stamping parts

Cables and metal stamping parts

Numerical control equipment and metal stamping parts

Numerical control equipment and metal stamping parts